Whether you’re an engineer in manufacturing, a design specialist in railways, or someone sourcing industrial components, you’ve likely encountered the annoying and sometimes damaging effects of equipment vibration. Over time, constant shaking doesn’t just wear out machinery; it rattles productivity, inflates maintenance costs, and in worst cases, triggers full-blown operational breakdowns.

Here’s the hard truth: Ignoring vibration isolation is like ignoring a slow leak in a boat. It may seem harmless at first, but sooner or later, it sinks your efficiency.

What if you could safeguard your systems with an affordable, scalable solution designed to increase the lifespan of your devices? Anti-vibration mounts are just what they sound like.

This article will explain the benefits of vibration isolation, the various kinds of anti-vibration mounts, typical blunders to avoid, and how to choose wisely, particularly if you work in heavy machinery, the automobile industry, or railroads.

Let’s get started.

Although vibration may seem like a small annoyance, it can have serious long-term implications. It can loosen fasteners, fatigue welded joints, misalign delicate components, and impair precision in systems that depend on performance.

These difficulties are faced on a daily basis by sectors including railroads, automobiles, and the maritime industry. The stakes are significantly higher here, and the operational environment is anything but predictable. Because vibration isolation is an operational requirement rather than merely a mechanical solution, anti vibration mount are crucial.

The right anti-vibration mount can be a game-changer for your equipment. Here’s how:

Think of it like shock absorbers in your car. Without them, every bump on the road would be a problem. Similarly, without vibration isolation, your systems absorb the full brunt of operational stress.

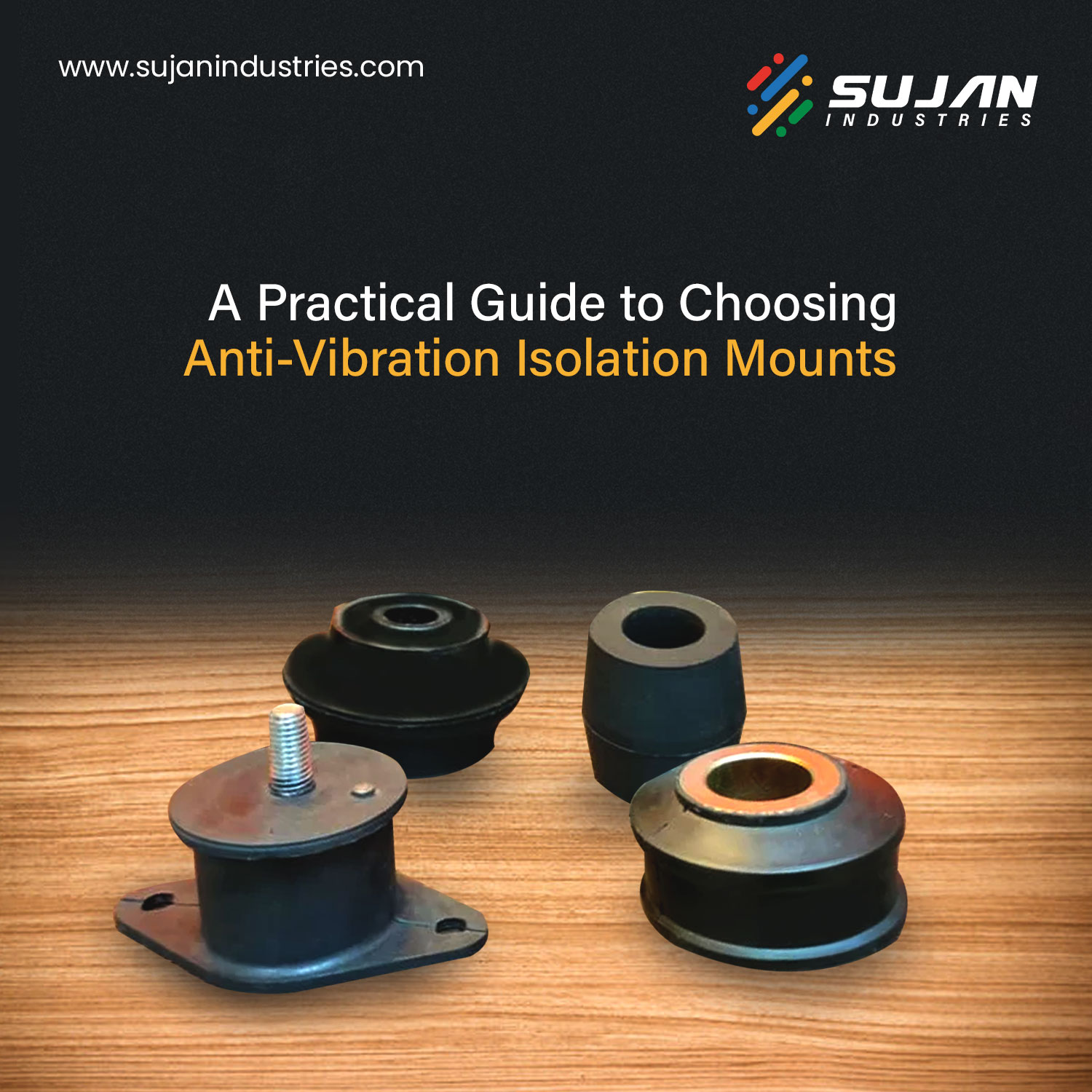

Choosing the right type is half the battle won. Here are the most commonly used anti-vibration mounts across industries:

Sandwich mounts, which have two metal plates with rubber attached between them, are perfect for heavy-duty applications. They are frequently found in industrial machinery, railroad applications, and construction equipment.

In applications requiring lower to medium vibration dampening, these are popular and adaptable.

Perfect for isolating low-frequency vibrations.

Great for applications with multi-directional vibration or shock loads.

Application, load dynamics, and environmental considerations for Indian railway components manufacturers frequently determine the appropriate kind.

Let’s be honest, getting this wrong can be costly and completely undermine effective vibration isolation. Here are some common pitfalls to avoid:

The truth is that there isn’t a one-size-fits-all solution. A thorough study of the equipment type, vibration frequency, weight distribution, and operating environment is necessary to select the best anti-vibration mount. The mount can be adjusted for optimal vibration isolation with additional data.

Selecting the best anti-vibration isolation mount is more about investing in the future of your equipment than it is about purchasing a component. Whether you work as an engineer at a manufacturing facility or as a procurement officer in the rail industry, this is one choice that will affect your business for the rest of its existence.

At Sujan, we don’t just supply parts, we deliver peace of mind. With decades of expertise in vibration isolation, our solutions are trusted by top railway parts manufacturers in India and across global industries. From sandwich mounts to bespoke designs, every product is backed by engineering precision and on-ground performance insights.

When performance matters and reliability is non-negotiable, trust Sujan, where engineering meets excellence.