Imagine a high-performance gearbox leaking oil mid-operation or a hydraulic pump losing pressure due to a faulty seal. For engineers, maintenance managers, and procurement professionals, such failures aren’t just inconvenient; they’re costly and disruptive. At the heart of many of these issues lies a small yet critical component, lip seals.

People often overlook these seals, yet they play a crucial role in preventing leaks, regulating pressure, and keeping pollutants out. Understanding these seals is critical when procuring from rubber product producers or maintaining sophisticated machinery.

This tutorial explores the fundamentals of lip seals, providing insights into their various forms, applications, and optimal installation practices.

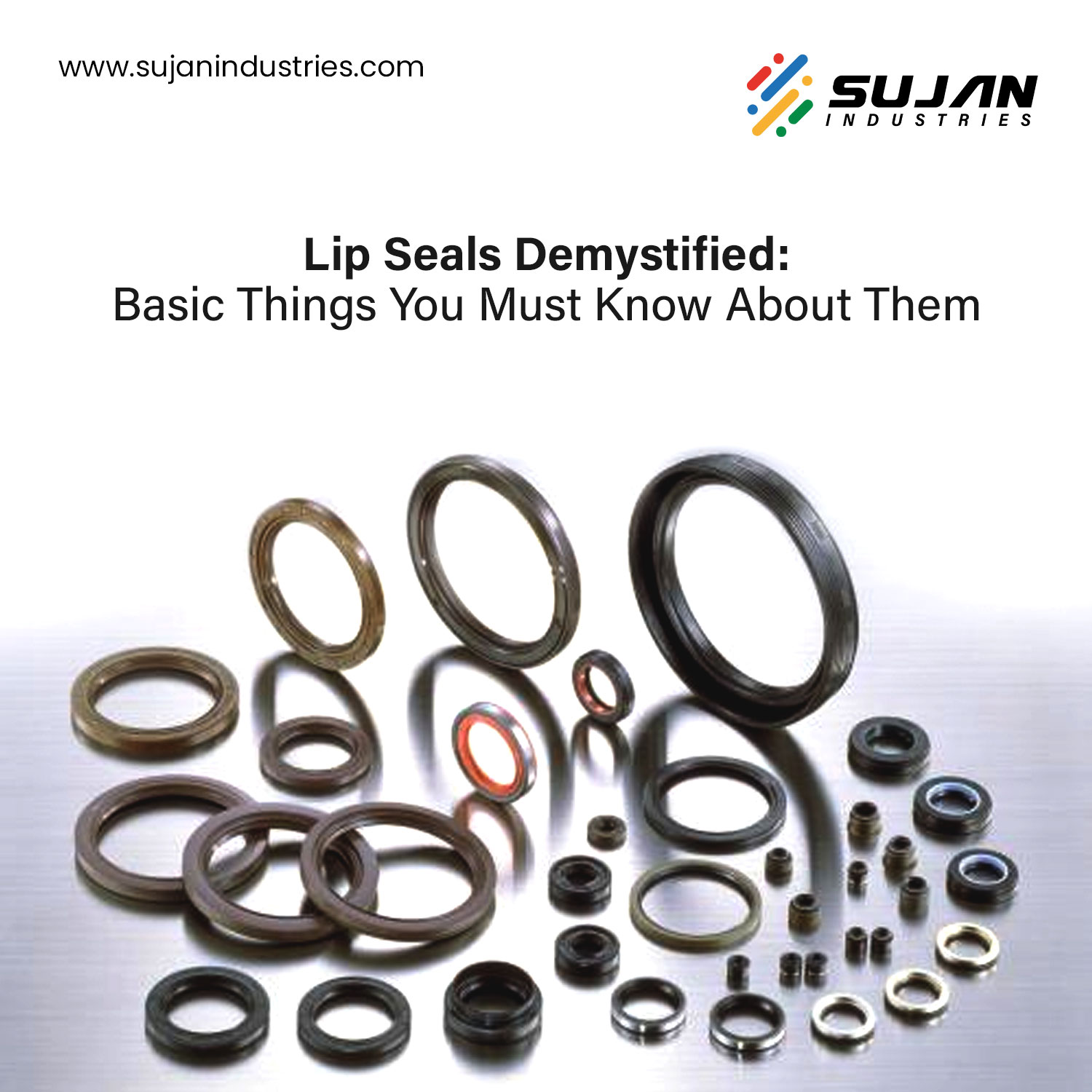

Lip seals, also known as oil seals or rotary shaft seals, are used to keep lubricants and pollutants out of rotating equipment. A flexible lip makes contact with a spinning shaft to form a barrier that keeps fluids in and blocks dirt and debris.

Engineers widely use these seals in automotive, industrial, and agricultural machinery to ensure durability and enhance performance.

Understanding the various types of lip seals is crucial for selecting the right one for your application:

These are the most frequent and versatile seals, with applications including rotating shafts and housing bores. They prevent lubrication leaks and shield against dust, grime, and moisture. They are commonly used in gearboxes, motors, and pumps, and are suitable for both low- and high-speed applications. Their design generally consists of a rubber or elastomer sealing lip supported by a metal housing.

Engineers design these seals for applications where the sealing surface sits perpendicular to the shaft axis, commonly using them in high-pressure systems like hydraulics and mobile machinery. They can tolerate harsh environments, including dirt, sand, and abrasive particles. Their strong design assures a lifespan in harsh settings, making them popular for construction and agricultural equipment. Many rubber product manufacturers in India now make high-performance axial face seals that satisfy international quality requirements and are suitable for demanding industrial applications.

These are all-rubber seals that extend across the shaft and seal against a perpendicular surface, giving a cost-effective secondary seal. V-rings are excellent for protecting primary seals from contaminants such as water spray, grease, and dirt. Their adaptability and simplicity of installation make them popular in electric motors, pumps, and drive systems.

These seals are specifically designed for dynamic applications, keeping lubricant and impurities out while withstanding high rotating speeds. They are critical in applications requiring heavy-duty machinery, vehicle drivetrains, and industrial processing systems. The robust materials used in these lip seals withstand wear and thermal expansion, assuring long-term performance in harsh situations.

Each kind serves a distinct purpose, and the choice is made based on working circumstances, shaft speed, environmental exposure, and lubricant type. Choosing the wrong kind can lead to early failure, costly repairs, and downtime.

The distinction between single and double lip seals lies in their design and application:

The choice between the two is determined by the operating environment. In dusty or unclean environments, double lip seals provide additional protection, increasing the life of the equipment.

Size selection is critical for the effective functioning of oil seals. An improperly sized seal can lead to leaks, premature wear, and equipment failure. Key dimensions to consider include:

Accurate measurements provide a proper fit, which protects the seal’s integrity and performance.

Lip seals’ function and lifespan rely heavily on proper installation. Here’s a checklist to help you:

Following these steps helps prevent common issues like leaks and premature seal failure.

Lip seals may be small in size, but their impact on machinery performance is anything but minor. Acting as the first line of defense, they prevent lubricant from escaping while shielding critical components from dust, dirt, water, and other contaminants. Without them, even the most robust machines can suffer from premature wear, reduced efficiency, or costly breakdowns.

If you’re searching for the top rubber products manufacturers, look no further than Sujan. At Sujan, we don’t just manufacture lip seals; we engineer reliability. Backed by decades of expertise and advanced facilities, we craft high-performance sealing solutions that industries trust worldwide.

As one of the leading rubber products manufacturers in India, we design and produce seals and gaskets that meet global standards for durability, precision, and efficiency. Whether it’s automotive, industrial, or heavy-duty machinery, Sujan’s seals are built to perform under pressure. Choose Sujan for quality you can count on, innovation that drives performance, and service that seals the deal.